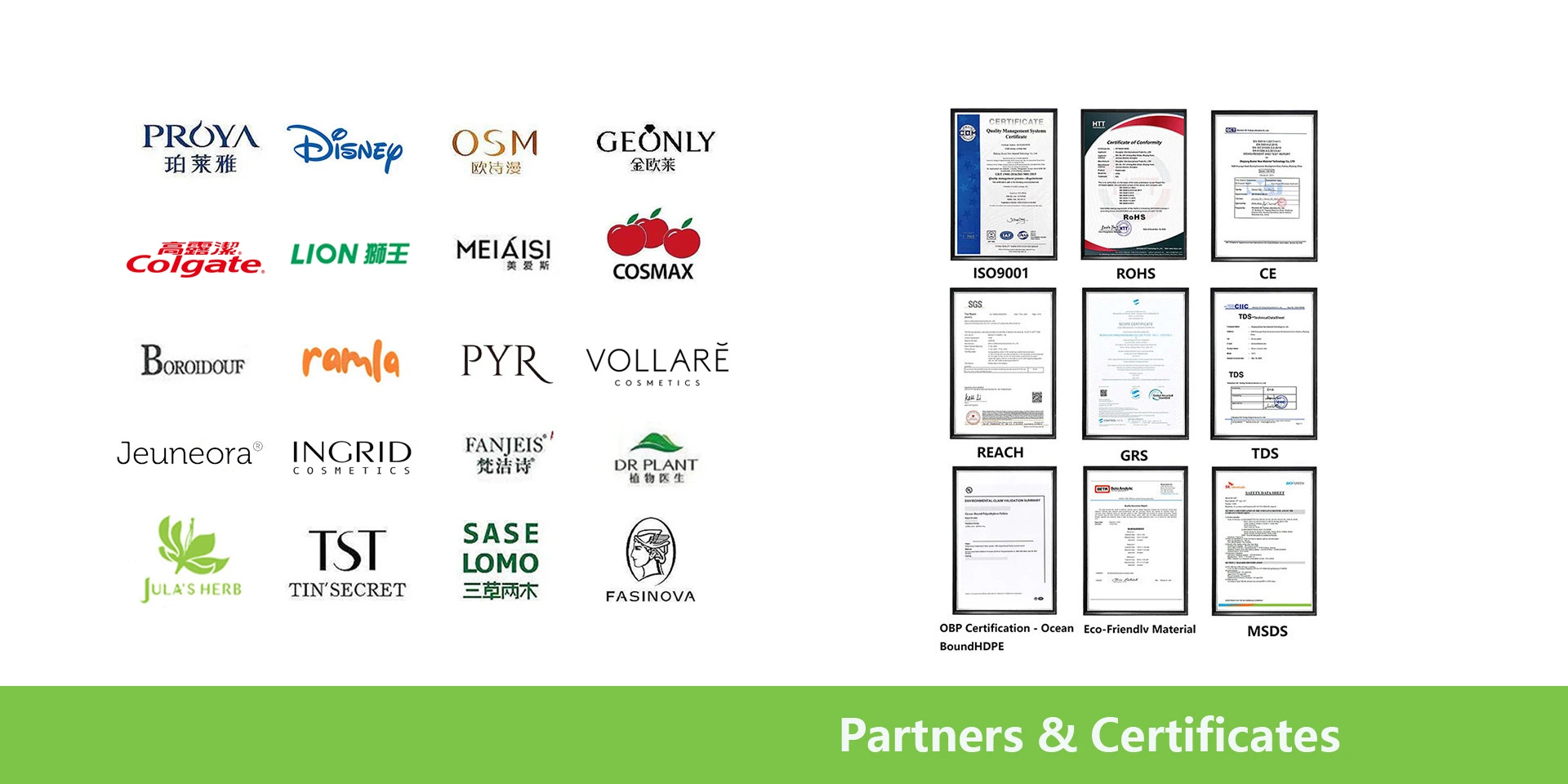

Global Top Intelligent Tube Packaging Manufacturer

Environmental Sustainability and Human Care

Our production system follows PROYA's strict standards, ensuring top-tier quality control. With three Swiss-imported tube-making machines, each worth $2 million, we achieve a daily output totaling 800,000 tubes. Supported by over a dozen production lines, our annual capacity exceeds 360,000,000 pieces tubes.

In the packaging world, some factories aren't selling you "Solutions"; they are selling you "Problems" that show up 3 months later in your warehouse.

If you're sourcing lip balm tubes, a "Yes-Man" factory is your biggest enemy. Here are the 5 red flags that prove a manufacturer is prioritizing your deposit over your brand’s survival.

Europe & the US — Evan

WhatsApp: +86 15221875884

Asia Pacific — Nick

WhatsApp: +66 807037251

Tel: +86-2167296126

E-mail: service@sampox.com

Finland Office:Kallantie 38A,45130,Kouvola

Head Office:Room 1109, Building 1, No. 159 Renqi Road, Fengxian District, Shanghai Oriental Beauty Valley

Factory Address: 1688 Chuangye Road, Meixi District, Wuxing Economic Development Zone, Huzhou City, Zhejiang Province

Thailand office: 98/314 Soi 11/6, Apitown, Phra Nakhon Si Ayutthaya District, Ayutthaya